Usefull Link

Contact Us

- 180027036400

- marketing@ynr-enggcluster.com

- VPO Rattangarh, Delhi Road, Yamuna Nagar-135001, Haryana, India

YEC is a service provider of material testing for a diverse range of materials, products, and technologies in advanced industrial supply chains where failure is not an option. We are providing the complete solution for the mechanical and chemical testing services of metals and polymers. Using our knowledge base we are taking up industrial R&D problems as a project and providing the analytical solution to the respective industries.

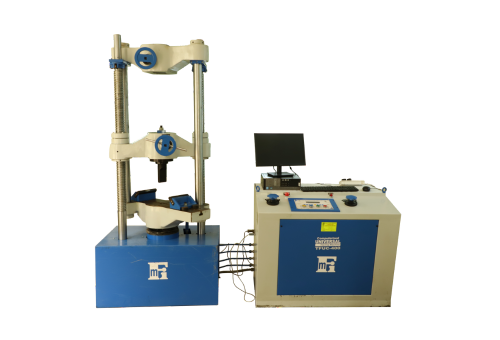

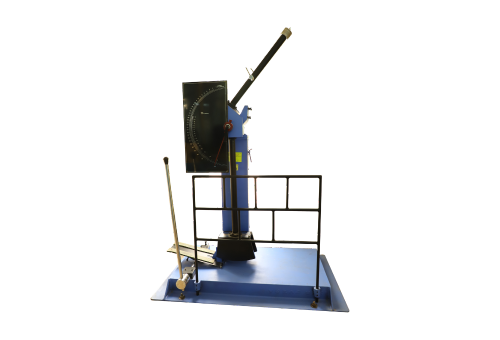

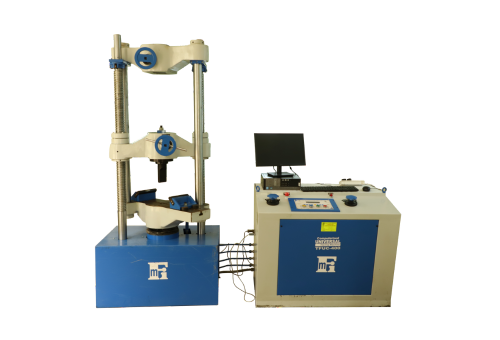

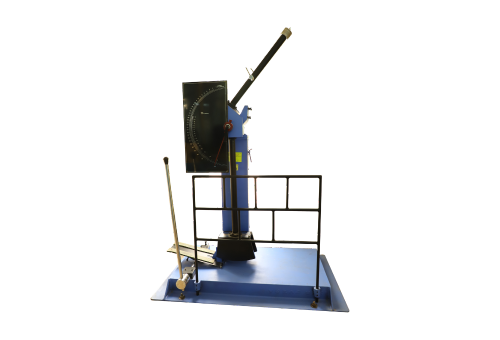

YEC offers mechanical testing of materials that cater to the market requirement for fast services and reliable results. We follow IS, ISO, ASME & ASTM standards for the testing of materials. Under tensile testing Ultimate Tensile Strength, %Elongation, Yield Strength (0.2% Proof Stress), and % Reduction Area are the parameters we are reporting to our customers.

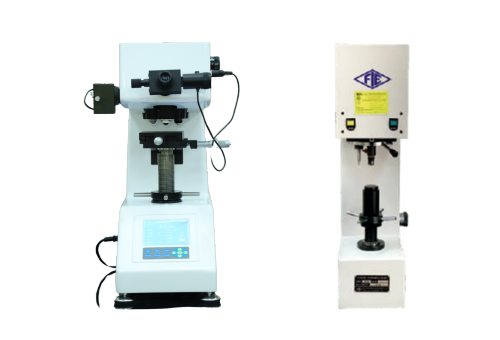

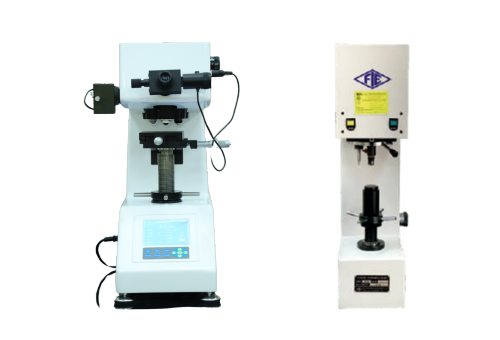

moreWe are also providing the service of Elevated Temperature Tensile Tests (ASTM E21, IS 1608-2, and BS EN ISO 6892-2) for specific applications/needs of our customers. For steel (TMT Bar), Rods, Sheets, Pipes, etc. Bend Test, Bend-Rebend, and Tensile testing can be carried out. YEC is also performing testing as per ASME sections specifically for welding test coupons (PQR) by conducting Root/Face/side bend tests as well as an impact test. We are conducting an Impact Test (Charpy & Izod) at Room temperature as well as at Sub-zero (up to -60oC) temperatures. YEC has a complete range of hardness testers like Micro Vickers, Vickers, Rockwell, Brinell, shore-A, and Shore-D Hardness Testers to cover a wide range of materials, coatings, and polymers.

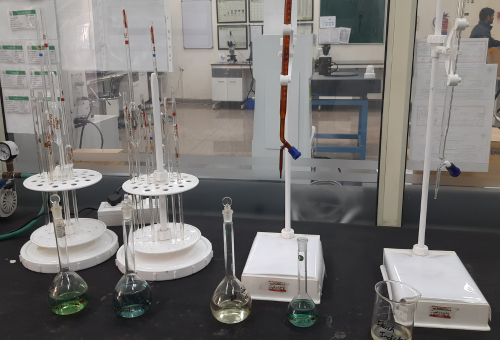

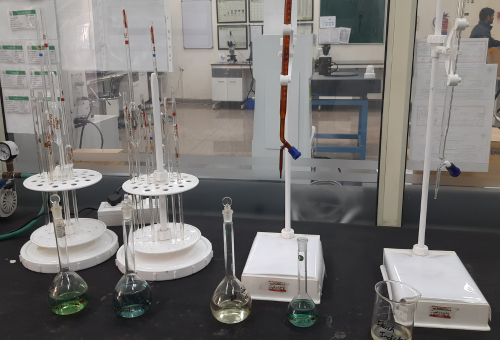

A remarkable feature of YEC is its ability to carry out tests on almost every element in the periodic table. Our lab is fully equipped with all the instruments necessary for both quantitative and qualitative analysis of metals. We employ the use of traditional methods such as Wet Analysis as well as instruments to study the prescribed process parameters.

moreA reliable optical emission spectrometer is a substantial part of our lab equipment. It is highly sensitive and capable of multi-element analysis. This method of metal analysis is widely used because it is based on highly reliable and powerful technology and alloys in solid form. The reason behind its popularity is fast speed, high accuracy, efficiency, and precision. Additionally, it can analyze up to 400 samples without requiring sample dissolution and it provides extremely high sample analysis outputs within a day. Spark OES requires significant quantities of reference material or data to achieve reliable and repeatable results. A comprehensive range of Certified Reference Materials (CRM) is available at YEC to cover the full range of metals.

We are conducting chemical testing for our clients to assure them of the quality of the material they are buying from the various vendors, we are also providing the services of failure analysis by conducting the chemical, metallography, and mechanical testing altogether. Using an Optical Emission Spectrometer we can verify the presence of any element on the solid (disc, bar, plate, etc.) material. Using Wet analysis we can analyze the chemical composition of any metallic chips, burs, and powder. We are taking care of the R&D projects of various industries by evaluating the complete material properties.

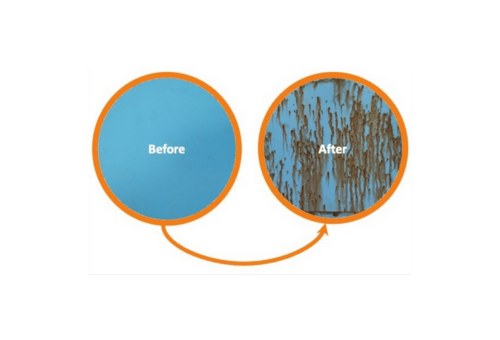

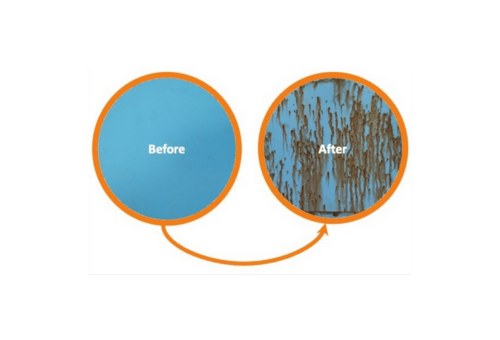

Corrosion occurs when the material of an article reacts with the environment, damaging the quality and shortening the life of the article. Corrosion severity is influenced by a variety of factors, among which are environmental factors, such as temperature, humidity, chemical composition, etc.

moreSeveral techniques can be employed to prevent corrosion, including corrosion testing. By using these methods, we can check if the material can withstand artificially induced corrosive environments without deterioration. Failure Analysis of a variety of commercially significant engineering materials can be performed using corrosion testing results. We at YEC are competent enough to undertake corrosion testing as per the specified National and International Standards.

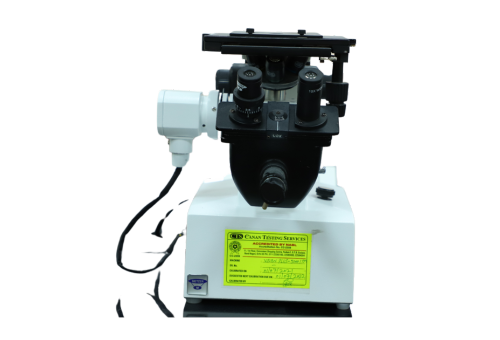

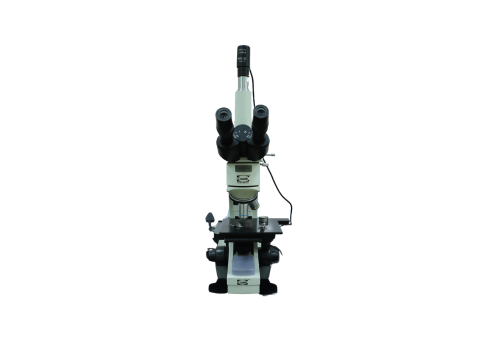

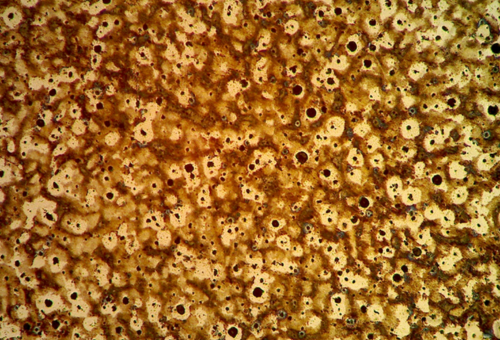

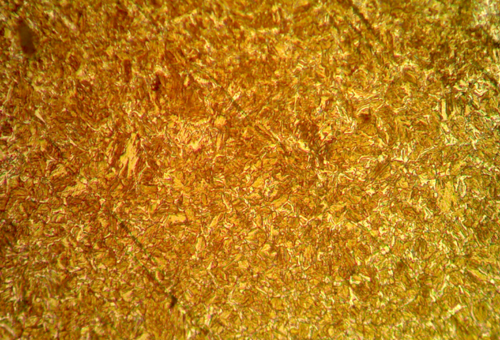

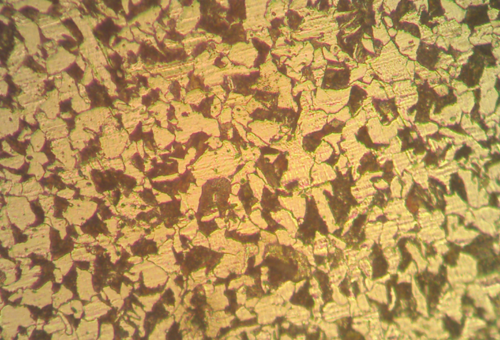

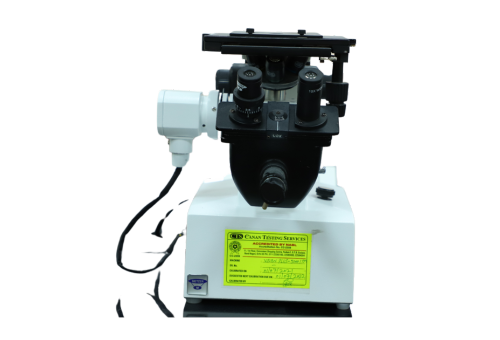

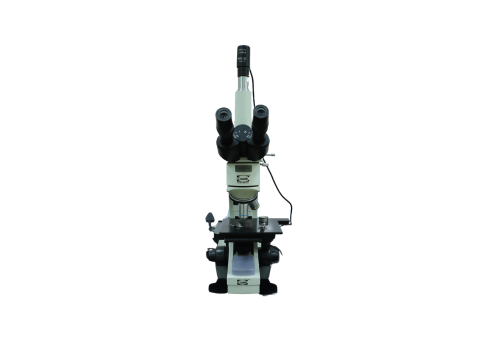

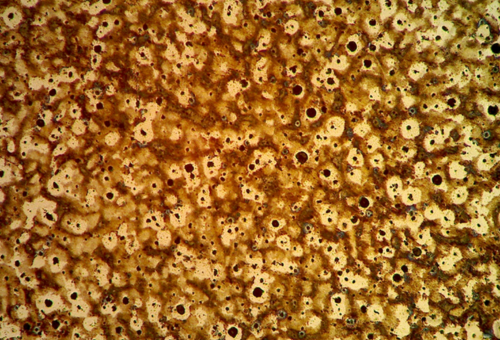

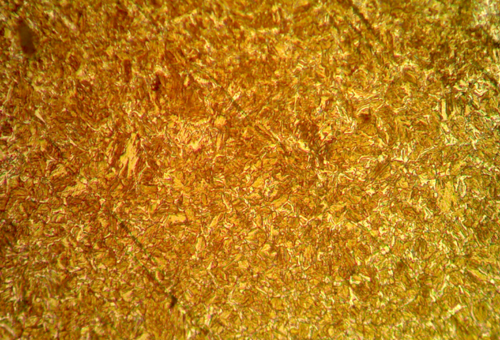

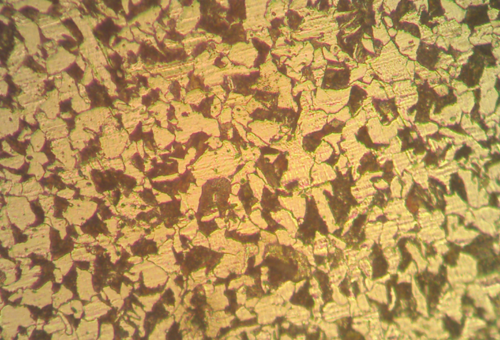

To determine the macro and micro scale visual characteristics of a material using metallographic testing, YEC uses standardized test methods. The information can be analyzed by a dedicated team to determine the material's current condition.

moreThis team can compare this information to the potential failures and remaining life of the material in a process component. In standard testing and failure analysis, metallographic examinations play a variety of roles. By using a light microscope, you can magnify the finest structures up to 1000 times. Microstructures of materials are studied by metallography. Analysis of a material's microstructure helps to establish if the material has been processed correctly. This is a critical step in determining product reliability and in understanding why a material failed.

YEC offers mechanical testing of materials that cater to the market requirement for fast services and reliable results. We follow IS, ISO, ASME & ASTM standards for the testing of materials. Under tensile testing Ultimate Tensile Strength, %Elongation, Yield Strength (0.2% Proof Stress), and % Reduction Area are the parameters we are reporting to our customers.

moreWe are also providing the service of Elevated Temperature Tensile Tests (ASTM E21, IS 1608-2, and BS EN ISO 6892-2) for specific applications/needs of our customers. For steel (TMT Bar), Rods, Sheets, Pipes, etc. Bend Test, Bend-Rebend, and Tensile testing can be carried out. YEC is also performing testing as per ASME sections specifically for welding test coupons (PQR) by conducting Root/Face/side bend tests as well as an impact test. We are conducting an Impact Test (Charpy & Izod) at Room temperature as well as at Sub-zero (up to -60oC) temperatures. YEC has a complete range of hardness testers like Micro Vickers, Vickers, Rockwell, Brinell, shore-A, and Shore-D Hardness Testers to cover a wide range of materials, coatings, and polymers.

A remarkable feature of YEC is its ability to carry out tests on almost every element in the periodic table. Our lab is fully equipped with all the instruments necessary for both quantitative and qualitative analysis of metals. We employ the use of traditional methods such as Wet Analysis as well as instruments to study the prescribed process parameters.

moreA reliable optical emission spectrometer is a substantial part of our lab equipment. It is highly sensitive and capable of multi-element analysis. This method of metal analysis is widely used because it is based on highly reliable and powerful technology and alloys in solid form. The reason behind its popularity is fast speed, high accuracy, efficiency, and precision. Additionally, it can analyze up to 400 samples without requiring sample dissolution and it provides extremely high sample analysis outputs within a day. Spark OES requires significant quantities of reference material or data to achieve reliable and repeatable results. A comprehensive range of Certified Reference Materials (CRM) is available at YEC to cover the full range of metals.

We are conducting chemical testing for our clients to assure them of the quality of the material they are buying from the various vendors, we are also providing the services of failure analysis by conducting the chemical, metallography, and mechanical testing altogether. Using an Optical Emission Spectrometer we can verify the presence of any element on the solid (disc, bar, plate, etc.) material. Using Wet analysis we can analyze the chemical composition of any metallic chips, burs, and powder. We are taking care of the R&D projects of various industries by evaluating the complete material properties.

Corrosion occurs when the material of an article reacts with the environment, damaging the quality and shortening the life of the article. Corrosion severity is influenced by a variety of factors, among which are environmental factors, such as temperature, humidity, chemical composition, etc.

moreSeveral techniques can be employed to prevent corrosion, including corrosion testing. By using these methods, we can check if the material can withstand artificially induced corrosive environments without deterioration. Failure Analysis of a variety of commercially significant engineering materials can be performed using corrosion testing results. We at YEC are competent enough to undertake corrosion testing as per the specified National and International Standards.

To determine the macro and micro scale visual characteristics of a material using metallographic testing, YEC uses standardized test methods. The information can be analyzed by a dedicated team to determine the material's current condition.

moreThis team can compare this information to the potential failures and remaining life of the material in a process component. In standard testing and failure analysis, metallographic examinations play a variety of roles. By using a light microscope, you can magnify the finest structures up to 1000 times. Microstructures of materials are studied by metallography. Analysis of a material's microstructure helps to establish if the material has been processed correctly. This is a critical step in determining product reliability and in understanding why a material failed.

Upload files in the Get Quote section and get a quote within 4 hrs

Technically qualified team in various mfg. technologies

Highly competitive prices and bulk discounts are also available