Usefull Link

Contact Us

- 180027036400

- marketing@ynr-enggcluster.com

- VPO Rattangarh, Delhi Road, Yamuna Nagar-135001, Haryana, India

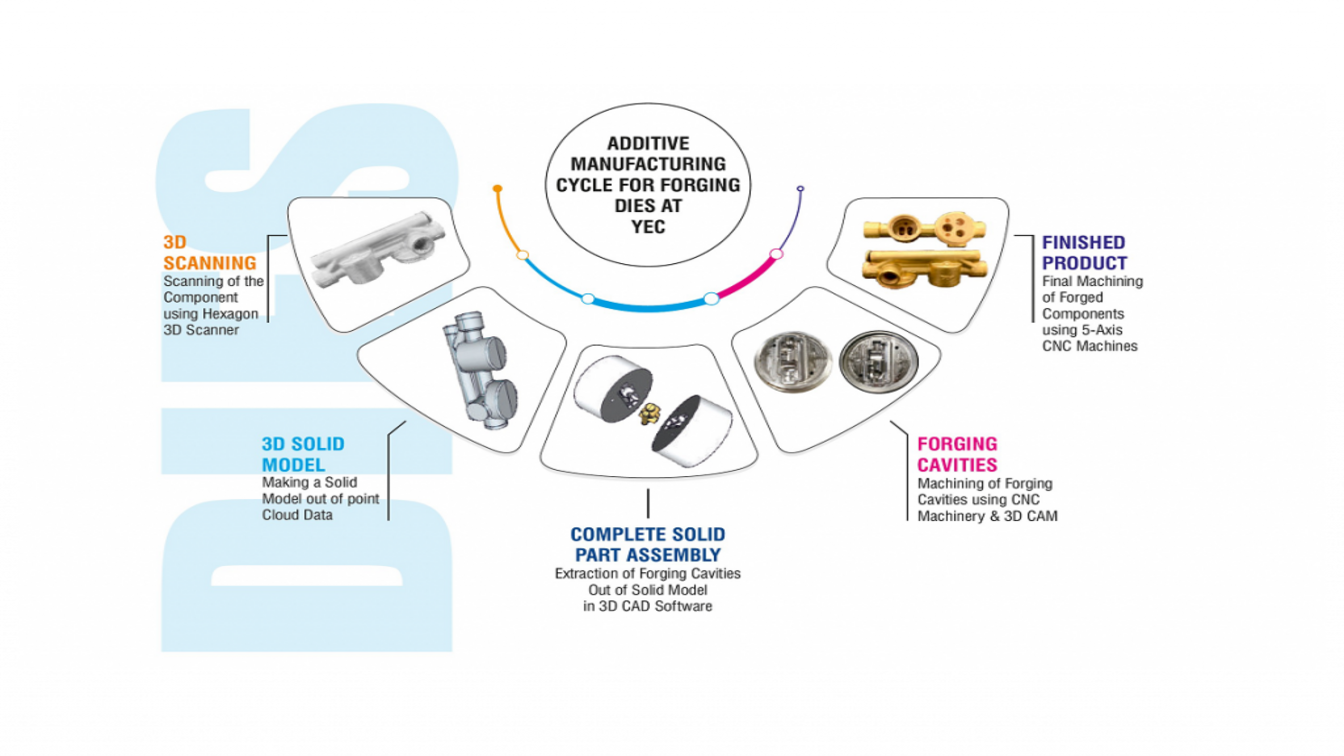

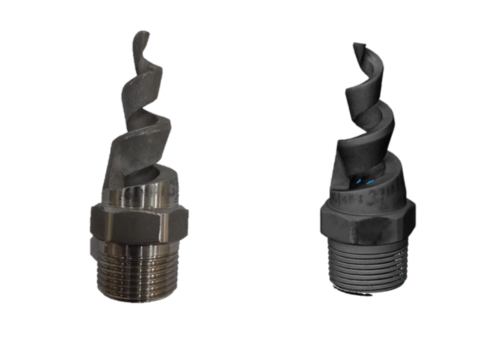

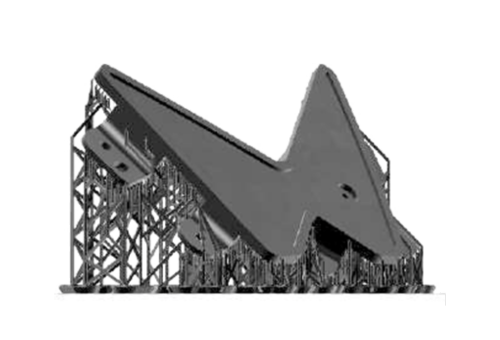

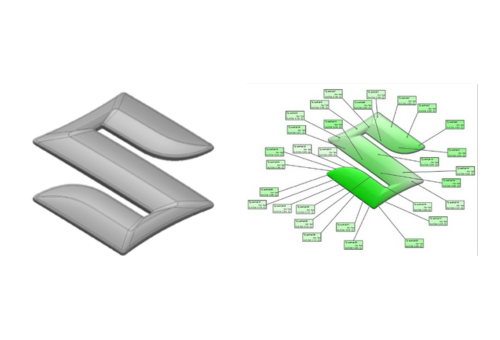

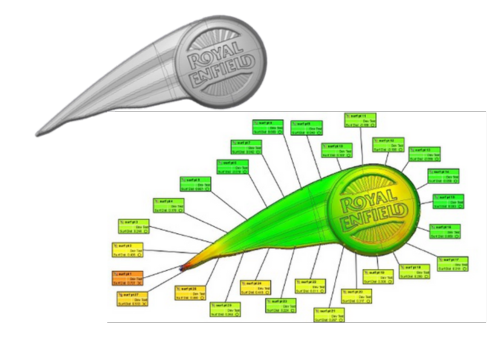

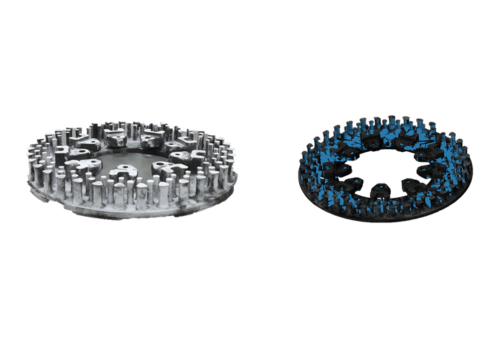

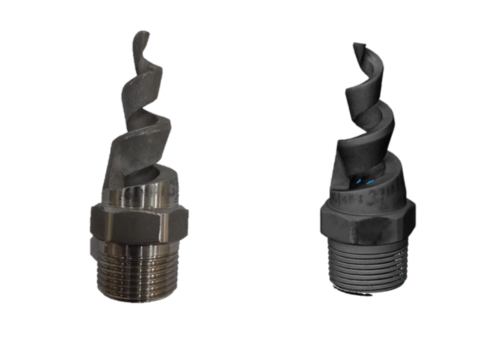

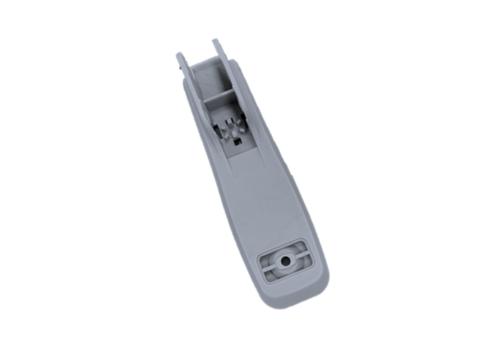

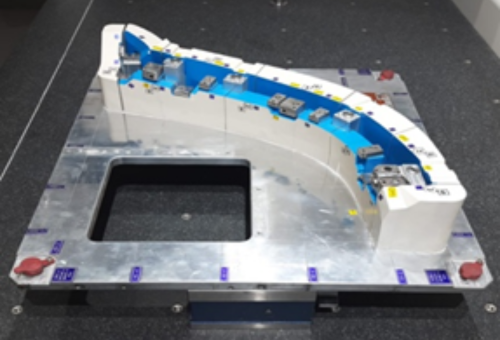

As a reverse engineering facility, we have the latest state of the art SLA based 3D printing technology installed at our premises; along with it, we have a portable 3D scanner that can be used at sites for scanning the various components and then creating a 3D model that is printable and can be easily fabricated.

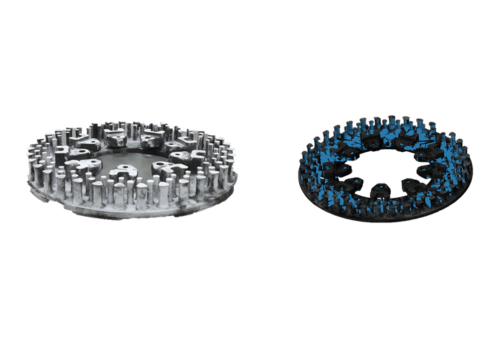

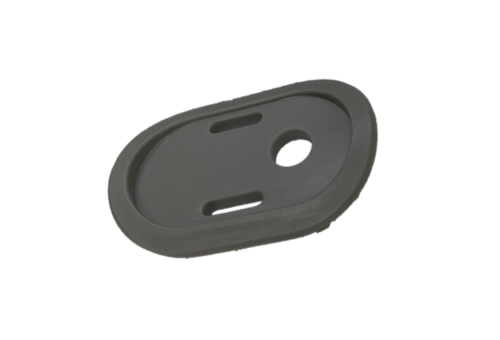

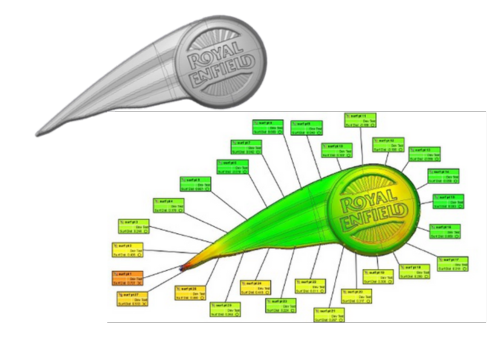

The YEC 3D scanning facility has state-of-the-art equipment capable of scanning objects from minute, highly detailed jewellery components to huge engineering components.

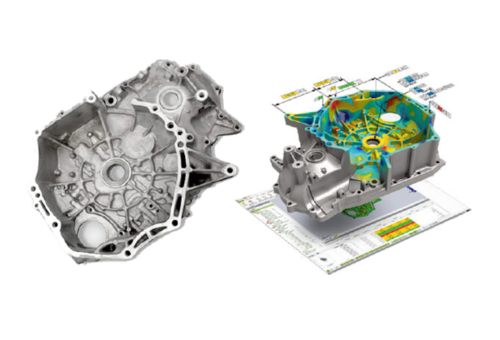

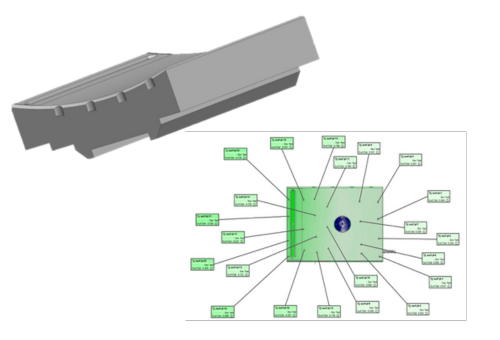

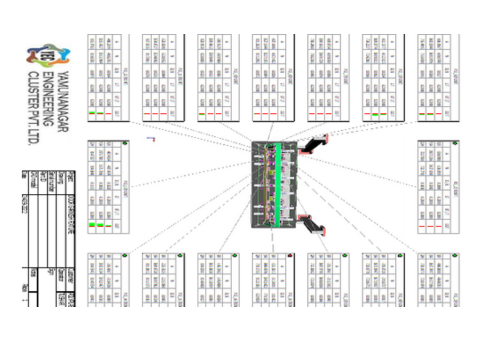

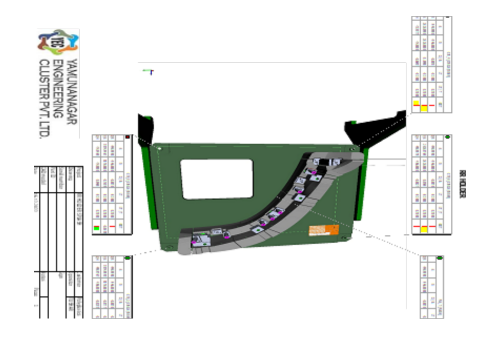

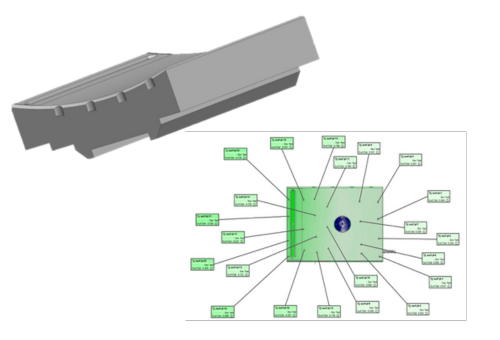

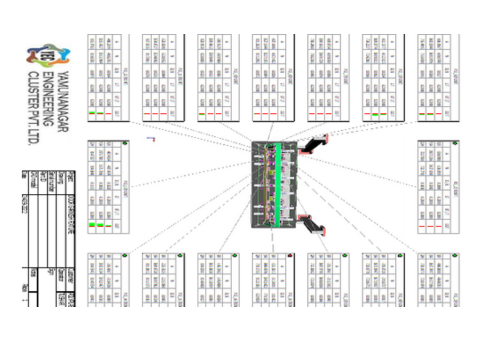

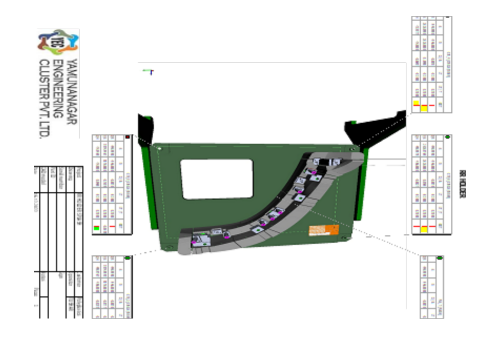

moreA detailed 3D scan report is generated using our 3D scanners to offer reverse engineering, dimensional inspection, and CAD mapping services.

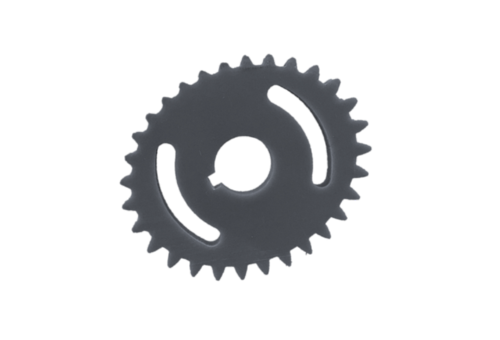

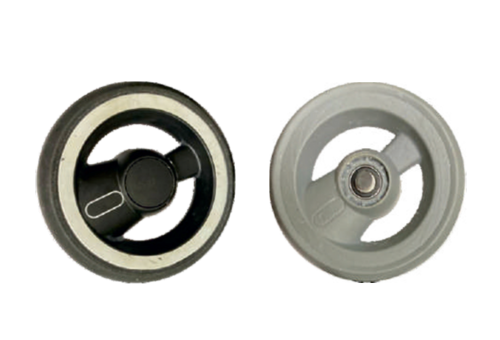

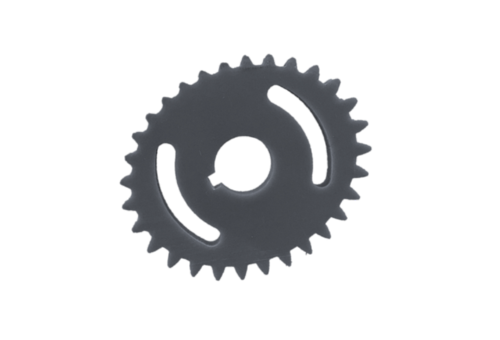

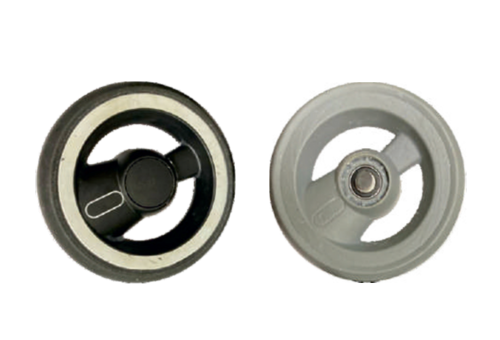

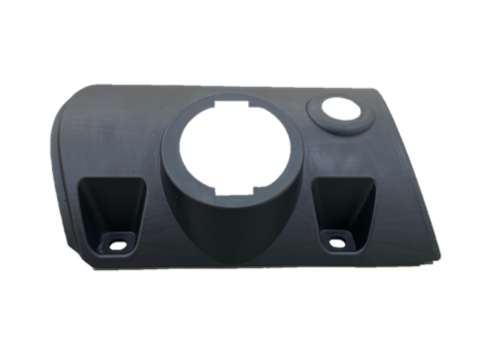

Our 3D Printing Service offers you the highly finished 3D printed components you need at an affordable price. Our company specializes in 3D printing, has 3D printing machines with the latest technology, and has skilled professionals with many years of experience working in the field.

moreTo meet the various industrial demands, YEC offers a wide range of services, including vacuum casting master copies, low-volume prototyping patterns, low-volume/limited edition products, with complex geometrical shapes, dental/jewellery/art, and other industries requiring high quality and finish, as well as visual prototypes used for photo shoots and market testing.

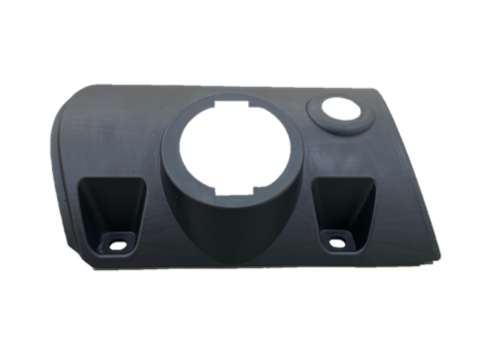

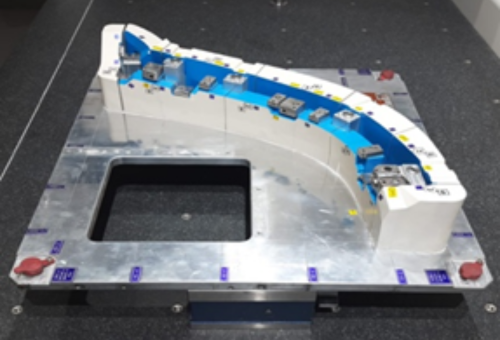

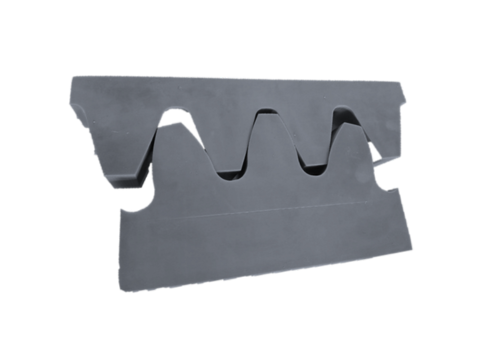

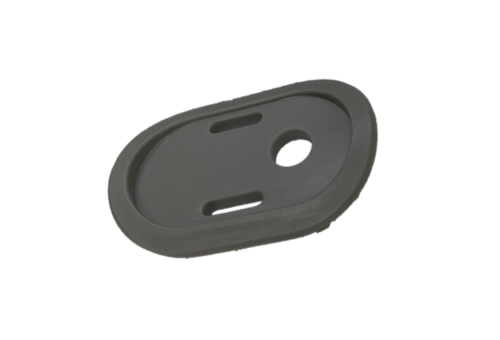

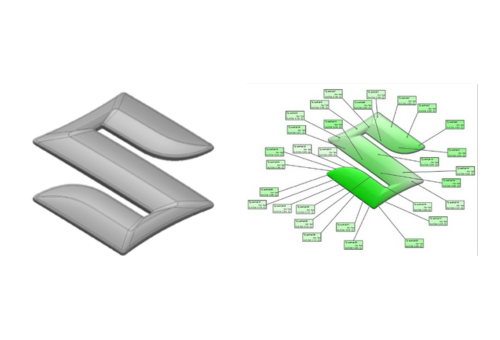

YEC is providing reverse engineering services to its customers, digitally capturing a physical object and creating a 3D digital file is known as reverse engineering.

moreWith years of experience in 3D Reverse Engineering Services, YEC utilizes a wide range of metrology equipment and hardware to convert a physical object into a digital file. With YEC, you can review both 2D & 3D detailed inspection reports in a comprehensive, easy-to-understand way.

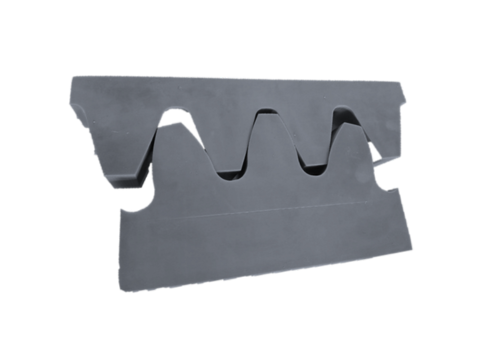

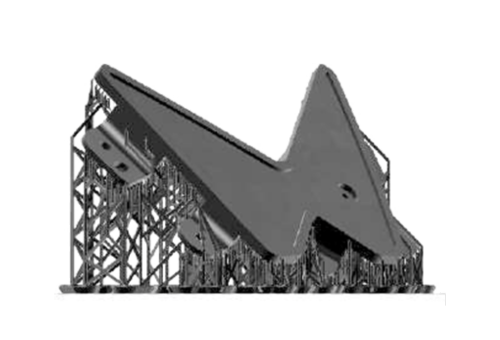

We provide rapid prototyping and 3D printing services for 3D-printed plastics, with a variety of materials and finishing options to choose from. Unlike traditional prototyping methods, 3D printing does not require tooling, so prototyping takes only a short time.

moreIn addition to geometric freedom, affordability is another advantage, especially when dealing with low volumes. Concept models are often produced using 3D printing, but functional prototypes can also be produced via precision technologies like SLA.

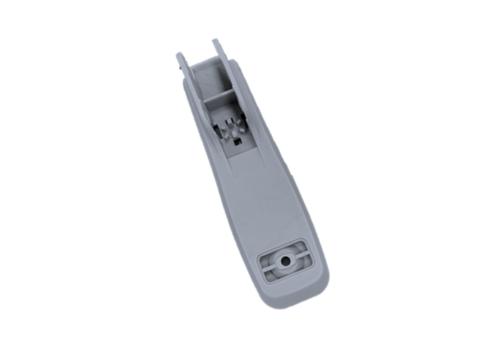

We have a portable 3D scanner that can be used at sites for scanning the various components and then creating a 3D model that is printable and can be easily fabricated.

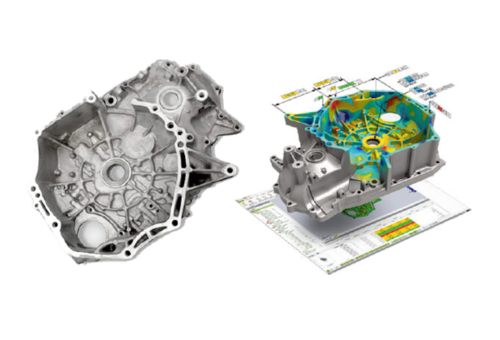

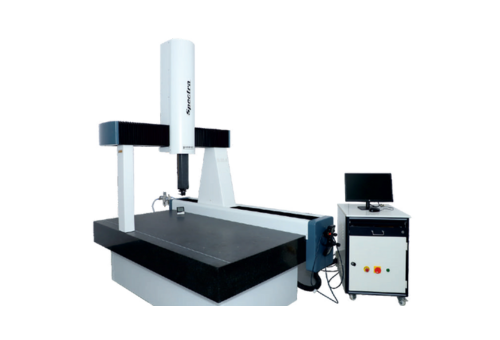

moreFor the accuracy of the machined and 3D printed components, we have our own in-house latest metrology equipment (CMM, VMM, etc.). This equipment provides inspection results that are highly accurate and precise; our workforce related to these activities has extensive experience in this field.

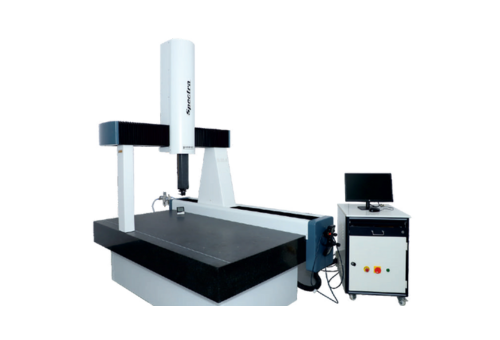

The CMM machine outpaces conventional methods in both speed and precision when it comes to consistently measuring components. Moreover, it enhances productivity while reducing the chances of measurement errors.

moreThe bottom line is that understanding what a CMM machine is, why you need one, and using one can help you save time and money as well as enhance the reputation and image of your business. A granite measuring table (800x1500x600), a "bridge" structure that travels vertically and horizontally above the table, a vertical beam that moves along the bridge structure, and a probe attached to the bottom of the vertical beam through a rotating joint make up the machine tabletop used by YEC. To reduce friction, the bridge traverse movement function is normally solely operated from one side and fitted with air bearings.

Using VMM present at YEC, we are measuring the geometrical and physical dimensions of any kind of component with a magnifying range of 30x-180x.

moreWe are reporting the basic linear, circular, and angular dimensions to our customers as per their requirements. All the measurements can be done on the X and Y-axis.

The YEC 3D scanning facility has state-of-the-art equipment capable of scanning objects from minute, highly detailed jewellery components to huge engineering components.

moreA detailed 3D scan report is generated using our 3D scanners to offer reverse engineering, dimensional inspection, and CAD mapping services.

Our 3D Printing Service offers you the highly finished 3D printed components you need at an affordable price. Our company specializes in 3D printing, has 3D printing machines with the latest technology, and has skilled professionals with many years of experience working in the field.

moreTo meet the various industrial demands, YEC offers a wide range of services, including vacuum casting master copies, low-volume prototyping patterns, low-volume/limited edition products, with complex geometrical shapes, dental/jewellery/art, and other industries requiring high quality and finish, as well as visual prototypes used for photo shoots and market testing.

YEC is providing reverse engineering services to its customers, digitally capturing a physical object and creating a 3D digital file is known as reverse engineering.

moreWith years of experience in 3D Reverse Engineering Services, YEC utilizes a wide range of metrology equipment and hardware to convert a physical object into a digital file. With YEC, you can review both 2D & 3D detailed inspection reports in a comprehensive, easy-to-understand way.

We provide rapid prototyping and 3D printing services for 3D-printed plastics, with a variety of materials and finishing options to choose from. Unlike traditional prototyping methods, 3D printing does not require tooling, so prototyping takes only a short time.

moreIn addition to geometric freedom, affordability is another advantage, especially when dealing with low volumes. Concept models are often produced using 3D printing, but functional prototypes can also be produced via precision technologies like SLA.

We have a portable 3D scanner that can be used at sites for scanning the various components and then creating a 3D model that is printable and can be easily fabricated.

moreFor the accuracy of the machined and 3D printed components, we have our own in-house latest metrology equipment (CMM, VMM, etc.). This equipment provides inspection results that are highly accurate and precise; our workforce related to these activities has extensive experience in this field.

The CMM machine outpaces conventional methods in both speed and precision when it comes to consistently measuring components. Moreover, it enhances productivity while reducing the chances of measurement errors.

moreThe bottom line is that understanding what a CMM machine is, why you need one, and using one can help you save time and money as well as enhance the reputation and image of your business. A granite measuring table (800x1500x600), a "bridge" structure that travels vertically and horizontally above the table, a vertical beam that moves along the bridge structure, and a probe attached to the bottom of the vertical beam through a rotating joint make up the machine tabletop used by YEC. To reduce friction, the bridge traverse movement function is normally solely operated from one side and fitted with air bearings.

Using VMM present at YEC, we are measuring the geometrical and physical dimensions of any kind of component with a magnifying range of 30x-180x.

moreWe are reporting the basic linear, circular, and angular dimensions to our customers as per their requirements. All the measurements can be done on the X and Y-axis.

Upload files in the Get Quote section and get a quote within 4 hrs

Technically qualified team in various mfg. technologies

Highly competitive prices and bulk discounts are also available